Application Areas

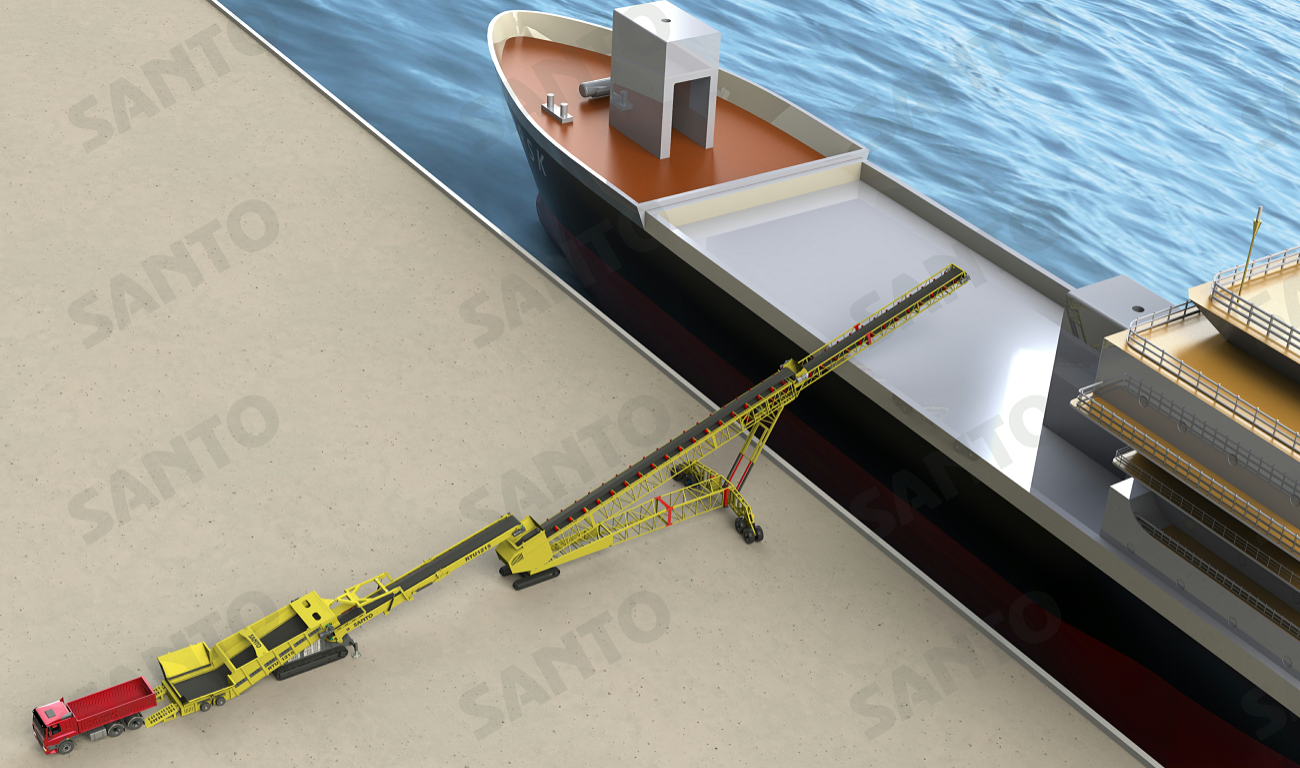

Coal Loading: At coal export ports, the mobile ship loader transfers coal from the stockyard to coal carriers. It can move flexibly and adjust its loading position according to different vessel types and cargo hold arrangements, achieving high loading efficiency.

Ore Loading: Suitable for loading ores such as iron ore and copper ore. The mobile ship loader can handle the characteristics of these materials, transferring them from the stockyard to the vessel to meet large-scale ore transportation demands.

Grain Loading: At grain export ports, the mobile ship loader conveys grain from warehouses or silos to transport vessels. Equipped with control and metering systems, it ensures loading quantity accuracy and maintains grain quality.

Ore Transfer and Loading: At mines close to ports, the mobile ship loader can be installed at the end of the transportation line to directly load processed ores—after crushing, screening, etc.—onto vessels for further processing or sale elsewhere.

Coal Transfer and Loading: Many power plants require large quantities of coal as fuel. The mobile ship loader can transfer coal from mines or intermediate transfer stations to vessels bound for the plant’s dedicated berth, ensuring stable coal supply.

Bulk Chemical Loading: Suitable for bulk chemicals such as fertilizers and soda ash. The mobile ship loader provides efficient loading operations while preventing contamination or leakage during the process.

Cement and Aggregate Loading: Cement plants and aggregate yards often use mobile ship loaders to load cement, sand, and gravel onto vessels for transport to construction sites or building material markets.

Key Advantages

Contact us today to learn more about our crawler-type mobile ship loaders and how they can benefit your operations.