In industrial material storage and handling, the efficiency, safety, and space utilization of stockpiling directly affect warehouse costs and production rhythm. Traditional methods that rely on fixed conveyors and manual labor often face challenges such as limited transfer flexibility, insufficient stacking height, and high costs. By contrast, mobile conveyors, with their adaptability to stacking operations, have become essential equipment for improving operational efficiency, offering significant value in industries such as coal, grain, and building materials.

The core demand of stockpiling is “higher and more organized” storage, and mobile conveyors achieve this through structural innovation.

Height Adaptability: With extendable and tiltable conveyor booms driven by hydraulics, mobile conveyors can flexibly adjust stacking height. Small models meet medium to low stacking needs of 3–10 meters, while heavy-duty models can exceed 20 meters, greatly increasing single-pile capacity and reducing yard space usage. At the boom’s discharge end, flow control devices ensure precise material placement, reducing spillage and ensuring pile stability.

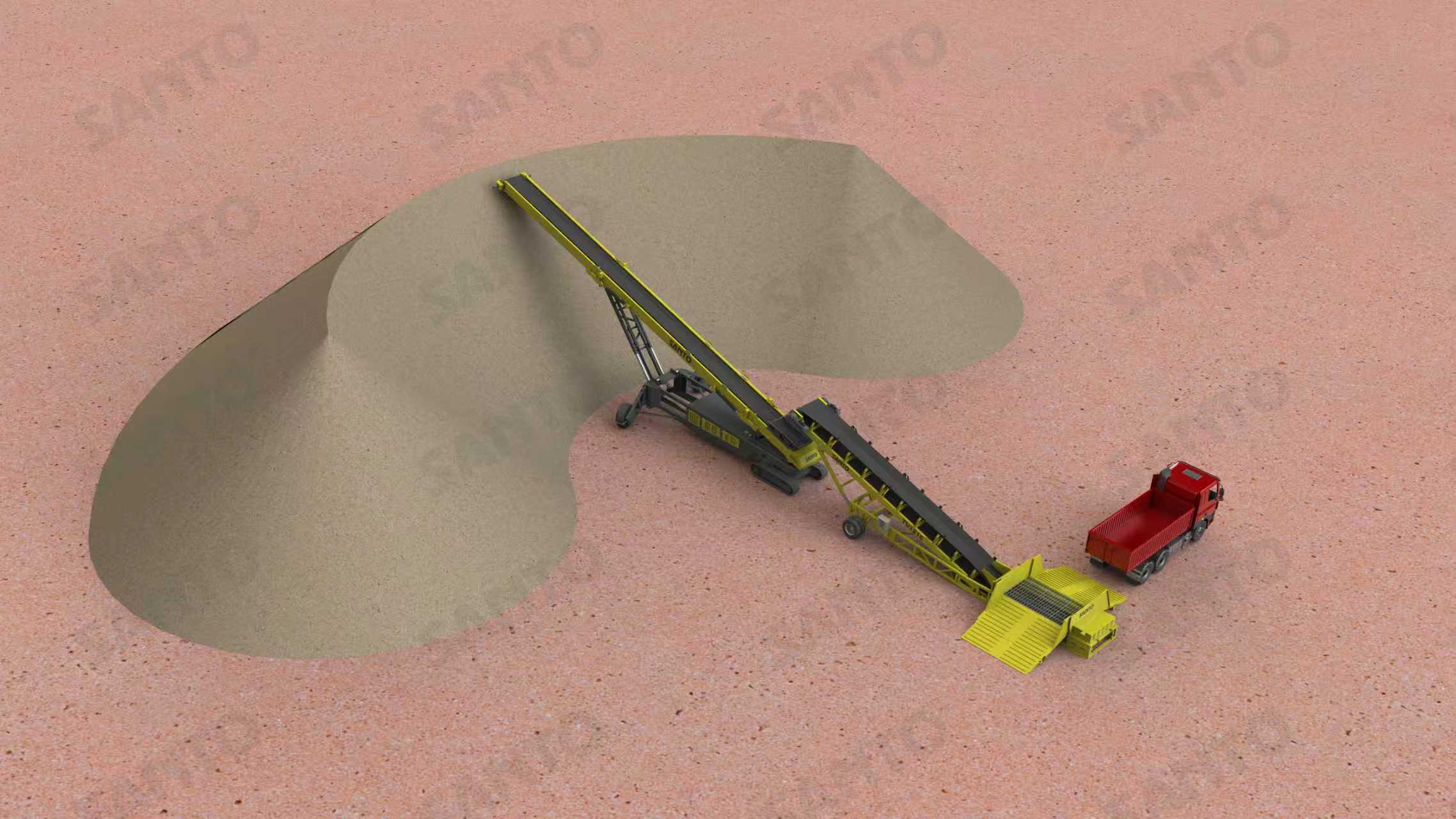

Pile Shape Adaptability: Mobile conveyors can move in a circular pattern around the stockpiling point, combined with boom angle adjustment, to achieve radial stockpiling and maximize space utilization. For example, in grain storage facilities, radial stockpiling allows for even ventilation of grain piles, reducing caking and mold.

Efficient stockpiling requires smooth coordination between transfer and storage, and mobile conveyors eliminate “transfer breakpoints.”

Fixed conveyors are restricted to set paths, requiring additional transfer points when the source or stockpiling location changes, leading to inefficiency and higher wear. Mobile conveyors, however, can directly link the two, eliminating the need for intermediate handling. For example, in construction batching plants, they can directly transfer sand and gravel from trucks into 12–15 meter aggregate piles, with no manual intervention, low loss, and high efficiency.

Additionally, mobile conveyors are “ready-to-use,” requiring only 1–2 hours on-site setup compared with several days for fixed conveyors. This makes them ideal for emergency storage and temporary stockyard applications.

Mobile conveyors help enterprises save costs on multiple fronts:

Equipment and Site Costs: No need for permanent foundations; high stacking efficiency increases yard storage capacity, reducing rental or expansion expenses.

Labor and Maintenance Costs: Only one operator is needed on-site, saving 3–5 workers compared with traditional methods. With a simple structure, maintenance cycles are extended by 50% and costs reduced by over 25%. Energy-efficient designs also cut power consumption by 15–20%, lowering energy bills.

Different industries have varying operational requirements, and mobile conveyors can be customized accordingly:

Heavy-duty and Abrasive Applications (coal, ore): Equipped with reinforced booms and wear-resistant belts, capable of handling large volumes, with dust-control systems meeting environmental standards.

Low-damage and Clean Applications (grain, food): Featuring food-grade belts and soft flow guides to minimize breakage, with some models equipped with temperature control to ensure product quality.

Challenging Site Applications (construction sites): Tracked or off-road wheeled chassis for muddy or rocky terrain, with high protection grades to withstand harsh environments.

From breaking stacking height limits and optimizing workflows to reducing costs and adapting to diverse scenarios, mobile conveyors are redefining material stockpiling. They are not only transfer tools but also key equipment for enterprises seeking higher efficiency and lower costs. With advancements in intelligent and green technologies, they will continue to provide new momentum for stockpiling operations across more industries.