Here are some common solutions for loading with mobile conveyors:

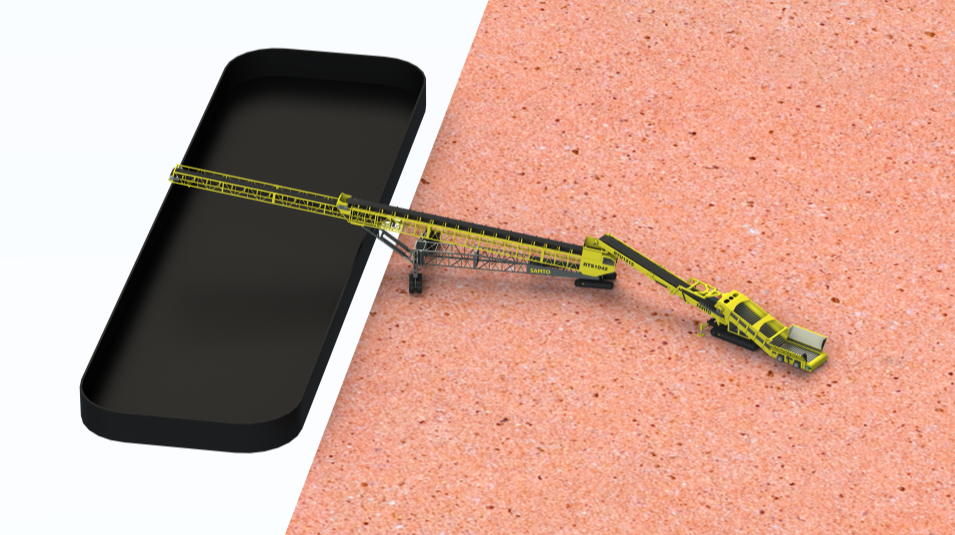

Solution description: Arrange the mobile conveyor on the shore so that its conveying arm can extend directly above the hatch of the ship. The conveyor receives the goods from the cargo storage area on the shore and continuously transports the goods to the ship through the conveyor belt.

Applicable scenarios: It is suitable for situations where the goods are concentrated on the shore and the berthing position of the ship is relatively fixed and close to the shore. For example, in some bulk cargo terminals, bulk goods such as coal and ore are usually piled up in the yard on the shore, and then directly loaded into the ship in this way.

Advantages: High loading efficiency, able to achieve rapid and continuous transportation of goods; relatively simple equipment layout, easy operation and easy maintenance.

Solution description: Use multiple mobile conveyors to shuttle inside the yard to collect and transport goods from different locations to the loading point on the shore. These mobile conveyors can flexibly adjust the walking route and operation position according to the distribution of goods and the progress of loading.

Applicable scenarios: Applicable to situations where the yard area is large and the distribution of goods is relatively scattered. For example, in some comprehensive port yards, there may be a variety of different types and specifications of goods stored at the same time, and the goods need to be collected from all corners of the yard for loading.

Advantages: Improve the utilization rate of the yard space, and be able to fully utilize the various areas of the yard to store goods; conveyors can be flexibly deployed according to the actual situation of the goods, and the flexibility and efficiency of loading can be improved.

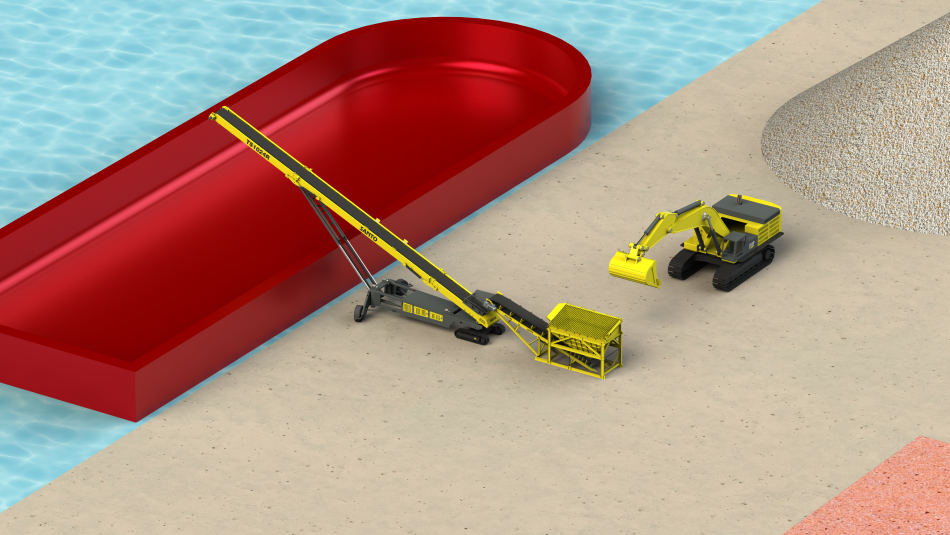

Scheme description: Set up multiple mobile conveyors at the front of the wharf to form a relay conveying system. The first conveyor receives the goods from the cargo stacking area, transports them to the next conveyor, and then passes them on in turn, and finally delivers the goods to the ship. Each conveyor can adjust the conveying speed and direction as needed to ensure smooth transmission of goods.

Applicable scenarios: Applicable to situations where the space at the front of the wharf is limited, but the goods need to be transported over a long distance before they can be loaded. For example, in some old wharves, due to historical reasons, the width of the front of the wharf is narrow, and large loading equipment cannot be arranged. At this time, a relay loading scheme can be adopted.

Advantages: It can realize long-distance transportation of goods in a limited space, improving the space utilization rate at the front of the terminal; through relay transportation, the transportation distance and load of each conveyor can be reduced, and the wear and failure rate of equipment can be reduced.

4. Ship self-carrying mobile conveyor loading plan

Solution description: A small mobile conveyor is carried on the ship. After the ship berths, the mobile conveyor extends directly from the ship to the shore or yard, receives the goods and transports them to the designated location on the ship. This solution is usually suitable for some small ships or ships with high requirements for loading flexibility.

Applicable scenarios: It is suitable for small ports or inland shipping, where ships frequently berth at different terminals and the cargo loading and unloading volume is relatively small. For example, some small container ships or inland bulk carriers can adopt this solution when loading and unloading cargo at some small terminals.

Advantages: The loading process is more flexible, and the ship can adjust the loading position and progress at any time according to its own operating needs; it reduces the terminal’s dependence on large loading equipment and reduces the construction and operation costs of the terminal.

SANTO has made ship loading solutions for many customers, and has won praise from customers for both the solutions and the product quality and service provider. If you want to customize your own shipping plan, you can contact us and our engineers will customize the most suitable plan for you based on your information.